CRANES

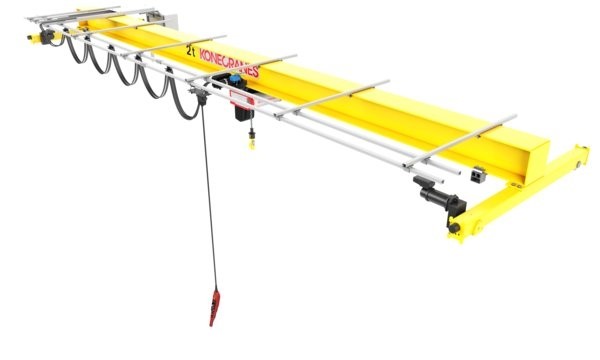

Also known as hoist cranes, overhead cranes operate from an overhead steel beam or pair of beams bridged between two structural supports; a trolley runs along these beams carrying a hoist, which is used to lift and reposition heavy loads. They are powered by hydraulics, internal combustion or electric batteries.

Regardless of a crane’s configuration, overhead cranes share three basic elements of construction: A bridge, a trolley and a hoist. The bridge is the overhanging arm that bears the weight of the lift; in bridge cranes and gantry cranes, the bridge spans two supports, while jib crane and cantilever crane bridges are suspended in air from one support; in these cases, the load bearing arm is often called a boom.

We offer a comprehensive range of cranes required for constructional use. These cranes are made in accordance with European standard specifications EN 13001. Our cranes are categorized as light duty cranes, medium duty cranes, heavy duty cranes and extra heavy-duty cranes.

We also offer service and maintenance facilities for cranes supplied by us. Specially designed, our cranes are fully accurate and give an optimum output. We can equip our cranes with optional features like magnetic or hydraulic brakes if a client needs enhanced effectiveness and safety.

Our main supplier for industrial overhead cranes is Konecranes. Konecranes overhead cranes utilize the latest technology to increase the safety and productivity of our customer’s business.

TYPES OF OVERHEAD CRANES:

Overhead cranes are quite diverse. They are available in a number of configurational varieties, including overhead stacker cranes, overhead jib cranes, overhead gantry cranes, and overhead bridge cranes.

Stacker cranes move vertically or horizontally on tracks so that they can reach and move items. They are used frequently as forklift alternatives in warehouse areas that are not appropriate for human access and with CNC operated warehouse systems.

Jib cranes are smaller, workstation-appropriate cranes, suitable for work on military vehicles and in industrial plants. Their movable hoist is supported on one side by a vertical support, called a jib or boom, or a wall fixture. From this support, a beam reaches out on a pivot as the trolley moves the hoist. Notice that jib cranes are not the same thing as semi-gantries, which have a fixed arm while jib crane arms can move horizontally at 180 degrees.

Gantry cranes are built atop gantries, which consist of two movable support structures used to straddle a workspace or object. Sometimes, a crane is only supported by one of these and a counterbalance. If this is the case, the crane is renamed a semi-gantry, half gantry, or cantilever gantry crane. Crane gantry subtypes include: ship-to-shore gantry cranes, full gantry cranes, portable gantry cranes, rubber tyre gantry cranes, and workstation gantry cranes, which work with smaller items in more compact environments.

Most often, gantry cranes are for large applications, such as bridge construction, monument construction, ship cargo loading and unloading, metalworking, and ship and vehicle movement.

Bridge cranes, sometimes called track cranes, are quite similar to gantry cranes, in that they both use structural support beams and a trolley to straddle their workload. The main difference between the bridge crane and the gantry crane is the fact that, while the structure of gantry cranes is usually completely mobile, bridge cranes have fixed structures, with only a movable hoist.

Tower cranes are cranes designed for demolition and construction applications. They feature: a tall mast, a bolted down base and a slewing unit used for rotation.

Mobile cranes are any portable crane. Mobile cranes are usually mounted on a land vehicle, ship or airplane for transportation.

Rubber tyre gantry cranes are mobile gantry cranes used to stack or ground containers.

Overhead shop cranes are overhead cranes used in auto shops. With it, workers in shops can access and work on the underside of vehicles.

Similar to overhead cranes are lifting mechanisms called electric wire rope hoists.

Electric wire rope hoists are used to lift and lower extremely heavy loads. Overhead electric hoists are mounted directly to the ceiling or to a single girder. They are driven by an electric motor and use wire rope, or wire strands surrounding a rubber core, to do the hoisting.